Comparing Dental Porcelains for Aesthetics and Durability

Exploring Dental Porcelains: A Comprehensive Comparison

Dental porcelains are vital in modern dentistry, offering solutions for restoring teeth with aesthetics, durability, and functionality. They are part of a broader category known as dental ceramics, which are used to fabricate crowns, bridges, veneers, and other restorations. Dental ceramics generally fall into three primary categories: predominantly glass, particle-filled glass, and polycrystalline ceramics. Each type varies in composition and properties, providing unique advantages based on clinical needs.

Leading cosmetic dentist, of San Francisco, Dr. Jorg-Peter Rabanus, examines five popular dental porcelains, comparing them for aesthetics, durability, and their ability to mimic natural teeth.

1. IPS e.max

Composition and Structure:

IPS e.max is a lithium disilicate-based glass-ceramic. It is known for its high strength and aesthetic qualities, making it one of the most popular choices for dental restorations. IPS e.max comes in two forms:

IPS e.max Press: A pressable ceramic for customized restorations.

IPS e.max CAD: Designed for computer-aided design and manufacturing.

Aesthetics:

IPS e.max is highly translucent and can mimic natural teeth exceptionally well. It comes in various levels of opacity (low, medium, and high), enabling it to suit different dental needs and tooth shades. The fluorapatite crystals in the material enhance its ability to replicate the brightness and translucency of natural enamel.

Durability:

With a flexural strength of about 420 MPa, IPS e.max is highly resistant to fracture and wear. This strength makes it suitable for anterior and posterior restorations, including crowns and small bridges. When bonded to the tooth, its toughness increases, reducing the risk of chipping or delamination.

Summary:

IPS e.max offers a perfect balance of aesthetics and durability. Its ability to mimic natural teeth makes it a preferred choice for veneers, crowns, and bridges.

2. 3G OPC Porcelain

Composition and Structure:

3G OPC is a unique porcelain system that offers high translucency and aesthetics. It is commonly used as an overlay material on zirconia-based frameworks.

Aesthetics:

This porcelain system is designed for its excellent translucency and ability to create lifelike restorations. It can enhance the hue, value, and chroma of restorations, making it ideal for front teeth where appearance is critical.

Durability:

While it is not as strong as IPS e.max, 3G OPC is chemically and physically compatible with strong zirconia cores, which increases its overall durability. However, its primary strength lies in its aesthetic enhancements rather than structural properties.

Summary:

3G OPC Porcelain is an excellent choice for aesthetic enhancements, especially in combination with durable zirconia frameworks.

3. Authentic Porcelain

Composition and Structure:

Authentic porcelain is a second-generation leucite-reinforced pressable ceramic. It contains fine particles that provide strength and translucency while maintaining a natural appearance.

Aesthetics:

Authentic porcelain offers 58 different ingots with varying opacity levels (20% to 70%), providing flexibility for natural-looking restorations. The fluorescent properties of the material emulate natural tooth vitality, even under different lighting conditions.

Durability:

The flexural strength of Authentic porcelain is approximately 148 MPa. While this is lower than IPS e.max, it is sufficient for veneers and anterior restorations. Its fine particle size (4 microns) ensures less wear on opposing teeth and helps prevent plaque accumulation.

Summary:

Authentic porcelain is a good option for veneers and crowns, particularly when natural aesthetics and compatibility with opposing teeth are priorities.

4. IPS Empress

Composition and Structure:

IPS Empress is a leucite-reinforced glass-ceramic that has been widely used in cosmetic dentistry. Although it has been largely replaced by IPS e.max, it remains relevant for certain aesthetic applications.

Aesthetics:

IPS Empress offers excellent optical properties, making it highly effective for mimicking the natural look of teeth. Its ability to replicate translucency and brightness is well-suited for anterior restorations.

Durability:

While not as strong as lithium disilicate ceramics, IPS Empress has a flexural strength of about 160 MPa. It is suitable for single-unit restorations like crowns and veneers but is not recommended for high-stress areas or bridges.

Summary:

IPS Empress is ideal for cases where aesthetics are the primary concern and the functional demands are moderate.

5. Zirconia-Based Ceramics (e.g., Lava Zirconia)

Composition and Structure:

Zirconia ceramics are polycrystalline materials containing no glass. They are incredibly strong and durable due to their densely packed crystalline structure. Lava Zirconia is a popular example.

Aesthetics:

Zirconia lacks the translucency of glass-ceramics like IPS e.max, making it less suitable for highly aesthetic cases. However, advancements in "high-translucency" zirconia have improved its optical properties.

Durability:

With a flexural strength exceeding 1,000 MPa, zirconia is the strongest dental ceramic available. Its toughness makes it suitable for posterior crowns, bridges, and even full-mouth reconstructions. Zirconia’s fracture resistance is unparalleled, and failures are rare.

Summary:

Zirconia is ideal for high-stress areas and cases requiring maximum durability, but it may not be the first choice for purely aesthetic restorations.

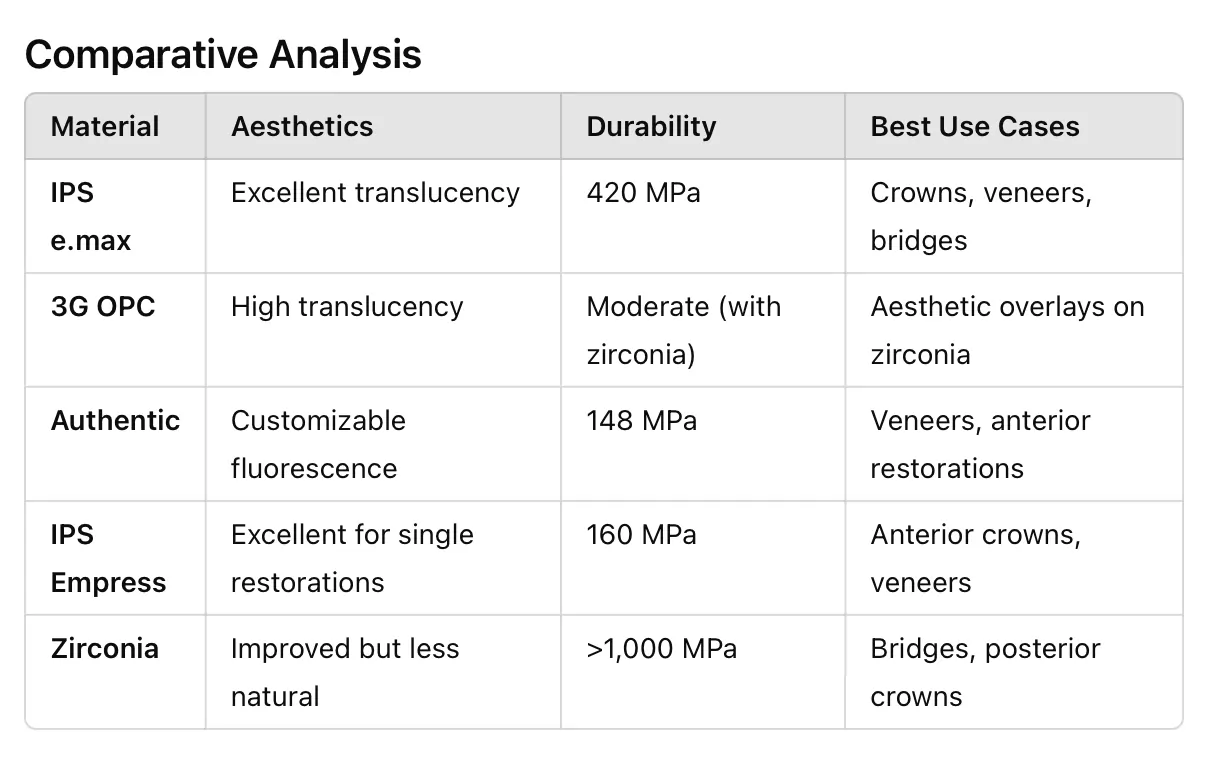

Comparative Analysis of Dental Porcelains

Conclusion

Dental porcelains have revolutionized restorative dentistry, offering a wide range of materials tailored to specific clinical needs. For patients prioritizing aesthetics, materials like IPS e.max and Authentic porcelain are excellent options due to their ability to replicate the natural appearance of teeth. On the other hand, zirconia-based ceramics are unmatched in strength and are suitable for areas requiring maximum durability.

Each dental porcelain has its advantages and limitations. The choice depends on the patient’s aesthetic preferences, functional demands, and the clinical expertise of the dentist. As advancements in dental materials continue, patients and practitioners have more options than ever to achieve durable, functional, and beautiful smiles.

Porcelains or ceramics fall into three categories:

- Predominantly Glass

- Particle-filled Glass

- Polycrystalline

In dental ceramics, the matrix is usually a glass that is lightly or heavily filled with crystalline particles or glass particles that melt at very high temperatures. Dental ceramics that contain predominantly glass best mimic the optical characteristics of enamel and dentin, the native layers of a natural tooth. Small amounts of filler particles control optical effects, such as opalescence, color (hue, chroma, value), and opacity.

Particle-filled glass ceramics contain additional filler particles for strength as well as thermal expansion and contraction. They are usually crystalline materials or high-melting glasses. The big plus about these particle-filled glass ceramics is that they can be etched, which creates a micro-retentive pattern that makes these dental porcelains bondable.

Polycrystalline ceramics contain no glass. The fillers are not particles but so-called "dopants" (atomic-level fillers). The atoms are packed into regular crystalline arrays, which makes the structure much more resistant to micro-cracks. This makes them the toughest and strongest dental porcelains on the market today. However, due to their toughness, 3-D computer systems are necessary to create well-fitting dental restorations or sub-structures. Their matrix is either aluminum oxide or zirconium oxide. Porcelains of this category are Procera, IPS e.max ZirCAD, Lava Zirconia, and Cercon Zirconia.

Dental materials are called "glass-ceramics" when the filler particles are created by special nucleation and growth heating treatments within the glass matrix. IPS e.max CAD and IPS e.max Press are examples of these particle-filled glass ceramics. They contain lithium-disilicate crystals as fillers, which gives them a significant increase of strength compared to high-glass leucite-reinforced glass ceramics, such as IPS Empress Esthetic.

The 3G OPC ceramic system's unique formulation results in a highly esthetic, translucent, and less abrasive "over porcelain". It has been a valuable choice for all-ceramic dental bridges that are used to replace missing upper front teeth. 3G OPC Porcelain is both chemically and physically compatible with zirconia-made products that are not glass infiltrated, such as Cercon and Procera. As zirconia-based core copings and multiple unit bridges become more and more common, there is a need to improve upon the overall esthetics of this strong and durable metal-free framework. 3G OPC overlays and core stain materials are used on top of zirconia cores to manipulate hue, value, and chroma of the restoration.

IPS Empress 2:

This dental porcelain is not produced anymore. It has been replaced by two later generations of porcelains: Eris (not in production anymore) and eMax. IPS Empress 2 was manufactured the same way as Empress 1, but consisted of completely different ingrediences. Whereas Empress 1 is a leucite-reinforced glass ceramic, Empress 2 porcelain consisted of a disilicate core that wass layered with a sintered glass ceramic. This sintered glass ceramic contained fluorapatite crystals similar to the needle-like fluorapatite crystals found in fluoride-enriched natural tooth structure. This process mimics natural tooth structure, not only in composition through the use of fluorapatite, but through the layering process of providing a strong dentinal framework overlaid with a translucent enamel-like layer. The sintered glass ceramic also has inherent fluorescence, opalescence, and an enamel-like translucency. With other systems that have tried multiple-unit, metal-free bridges over the years, the underlying framework was opaque and ruined the benefits of being metal-free because it still ended up with an opaque-looking bridge. Empress 2 restorations looked much better. The framework actually became more translucent during the fabrication process and complimented the underlying tooth structure as soon as it is in the mouth. Additionally, the framework itself had an incredibly polishable surface and high wear compatibility with the opposing natural teeth. Older generation ceramics had been too brittle and hard and caused a wear of the opposing natural teeth. Empress 2 had nearly three times the strength and three times the fracture toughness as the original material. Therefore it was for a certain period the only metal-free material that was specifically useful for cosmetic three-unit bridges.

Authentic:

Authentic is a great dental veneer porcelain. It is a second-generation Leucite-reinforced pressable ceramic. This porcelain was originally introduced by Ceramay into the European market in early 1998 and was subsequently introduced by Microstar Corp. to the U.S. market in September of 1998. It offers 58 different fluorescent pellets (pressable ingot) choices in four opacity levels ranging from 20%, 30%, 45% and 70% opacity. The vitality and fluorescence of the final porcelain veneers and porcelain crowns are associated with the properties of these ingots. With each increase in ingot opacity, additional fluorescence is added to increase vitality, which can emulate the natural dentition in all lighting sources.

This brand of crown and veneer porcelain is extremely kind to opposing tooth structure in terms of wear characteristics. Natural tooth structure has a VH (Vickers hardness) of 450, while most veneer porcelains range between 700 and 900. The composition and average particle size of Authentic porcelain contribute to its low VH. Due to an average particle size of just 4 microns, it makes it more difficult for dental plaque to form.

The flexural strength of this dental porcelain is 148 MPa. Its overlay ceramic measures 90 MPa. Authentic porcelain veneers always require dentin bonding.

IPS e.max:

IPS e.max is an aesthetic and high-strength dental porcelain system. IPS e.max Press are glass-ceramic ingots in three levels of opacity and in 2 sizes. The ingots exhibit an optimized homogeneity, which results in a strength of about 400 MPa. Therefore, the ingots are suitable for fabricating single crowns and bridges in the anterior and premolar region.

They have three levels of opacity: low translucency (LT), medium (MO) and high opacity (HO). This allows us to fabricate lifelike aesthetics independent of the shade of the prepared tooth. These porcelain restorations can be delivered by adhesive, self-adhesive and conventional cementation.

IPS e.max ZirPress porcelain system is a glass-ceramic ingot for the PRESS-ON technique. This dental porcelain system uses fluorapatite glass-ceramic ingots to be pressed on IPS e.max ZirCAD frameworks. This allows the fabrication of zirconium oxide-reinforced crowns and multi-unit bridges. The strength of zirconium oxide frameworks is combined with the aesthetics of the press ceramic in the press-on technique. The ingots are used to press onto both IPS e.max ZirCAD and other zirconium oxide frameworks in the CTE range of 10.5 - 11.0. The fluorapatite crystals contained in the ingots control the interplay of translucency, opacity and brightness. Therefore, the less translucent zirconium oxide frameworks are optimally masked.

Pressed versus Feldspathic Porcelains

In the past, feldspathic porcelain was considered closer to replicating nature than pressed porcelains. The most contributing factor used to be that using the feldspathic technique, the ceramist could build the porcelain veneer in layers, which gives the veneer a depth that mimics nature. However, pressable porcelains can also be layered and mimic nature. Pressed ceramic systems, such as Empress and e.max (Ivoclar) or Authentic (Jensen), have a wide array of porcelains that compare to feldspathic systems. This means that pressed porcelain veneers can have depth and vitality.

While feldspathic porcelains allow for very conservative tooth preparations, they are too weak when porcelain is to be extended more than 2 mm beyond the preparation surface of the tooth. Its flexural strength is about 100 MPa compared to the strength of Empress and Authentic, which is about 168 MPa. And even these have their limits. If a porcelain restoration needs to be extended by more than 4 mm, e.max Press or e.max pressed to zirconia should be considered.

There is an inherent advantage when using pressed ceramic systems for full-mouth reconstructions. They can be waxed to full contour and have the function worked out before the units are pressed. Feldspathic porcelains, on the other hand, need to be built layer by layer while working out the function. However, there are clinical indications for each porcelain. It also depends on the personal goals of a patient.

In any case, one more very important aspect of cosmetic dentistry should be mentioned: the Diagnostic Wax-Up

IPS e.max Press versus zirconia

IPS e.max Press is an alternative to IPS Empress in the posterior area because it is about two and a half times stronger than IPS Empress. The flexural strength of IPS e.max Press is about 420 MPa. IPS e.max Press is made of lithium disilicate, a monolithic material. It is even stronger when pressed to a zirconia core, which has a strength of more than 1000 MPa. Failures in these restorations are rare and occur in the porcelain ("delamination").

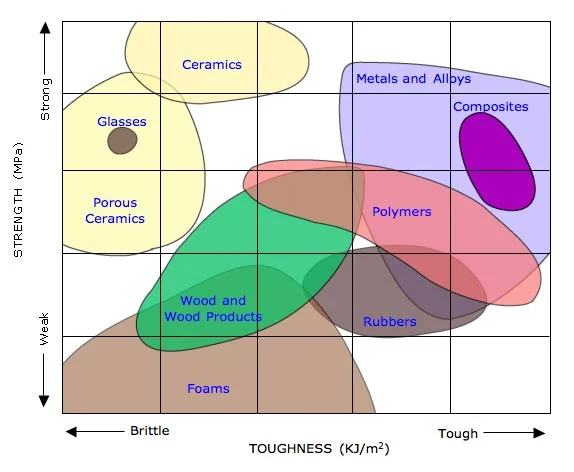

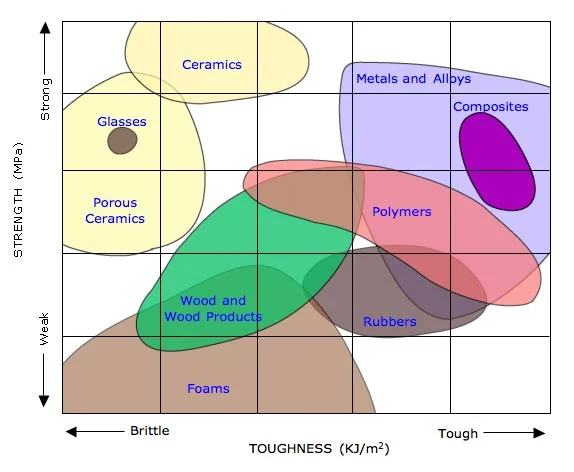

Some references consider e.max Press more fracture resistant than zirconia restorations. The reason is the higher "toughness" of e.max as compared to zirconia. So, even though zirconia is "stronger" it is not as "tough" as e.max. Interesting, isn't it? While the terms toughness and strength descibe the quality of a material, they are defined differently:

Toughness:

The ability of a structural material to resist shock or impact; its ability to absorb energy before fracture.

Strength:

Strength measures the resistance of a material to failure, given by the applied stress (or load per unit area).

Toughness and Strength are related. A material may be strong and tough if it ruptures at high strains exhibiting high forces. The term "toughness" describes the way a material reacts under sudden impacts. Brittle materials may be strong but not tough. Strength is a term that indicates how much force can the material support, while toughness indicates how much energy a material can absorb before rupture. In short, the opposite if tough is "brittle." A good example of a tough material that has low strength is rubber. A good example for a strong material that is brittle is porcelain.

Bottom Line:

IPS e.max is tougher (less brittle) than zirconia with porcelain.

References

Denry I et al. Ceramics for Dental Applications: A Review. Materials 2010, (3); 351-368.

Usha G et al. Advanced Ceramics - A Review of Material Science. J of Dental Sci and Res 2014, 5(2); 5-11.

Kelly JR. Dental Ceramics: What is this Stuff Anyway. J Am Dental Assoc 2008, 139; 4S-7S.

Haller B et al. Bonded All-Ceramic Restorations with the IPS Empress System. Pract Periodontics Aesthetic Dentistry 1994, 5(7); 39-48.

Morig G. Aesthetic All-Ceramic Restorations: A Philosophic and Clinical Review. Pract Periodontics Aesthetic Dentistry 1996, 8(8); 741-749.

Pallis K et al. Fracture Resistance of Three All-Ceramic Restorative Systems for Posterior Applications. J Prosthetic Dentistry 2004, 91(6); 561-569.